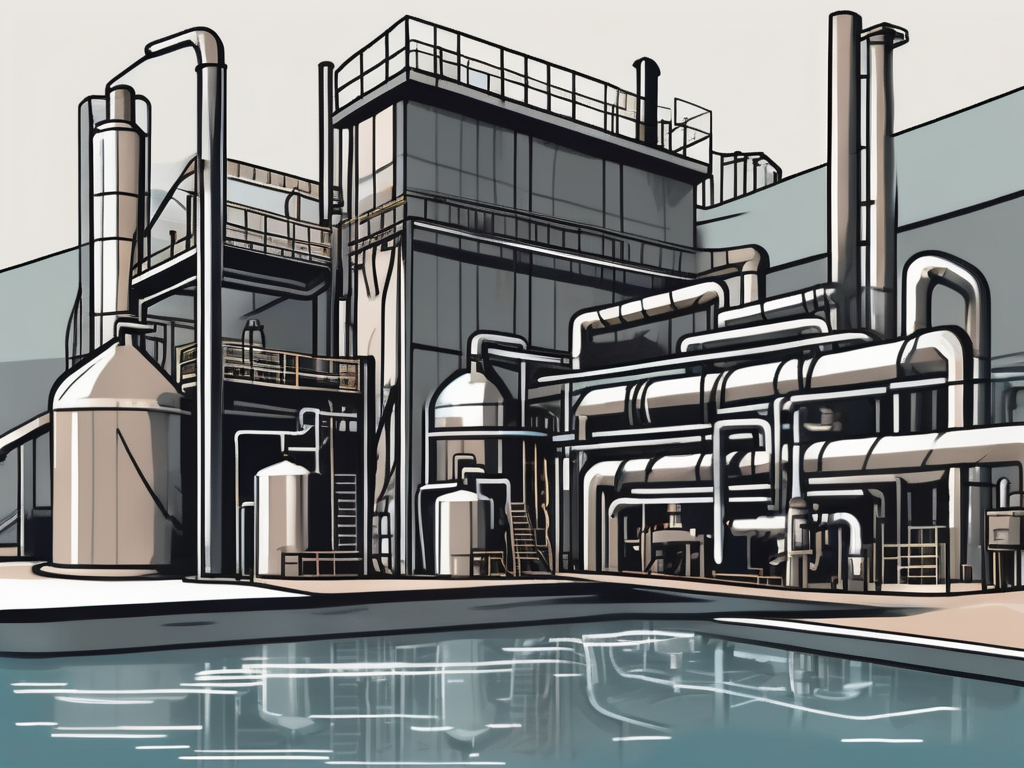

Discover how the steel industry in North America is leading the way in sustainability with over 95% of its water being recycled.

Steel production is a vital industry that contributes to the infrastructure of modern society. However, the process of producing steel requires significant amounts of water. To mitigate the environmental impact of water consumption in steel manufacturing, the industry has made considerable progress in water recycling. Today, more than 95 percent of the water used in North American steel production is recycled, demonstrating the industry’s commitment to sustainability and resource conservation.

Understanding the Steel Production Process

The Role of Water in Steel Manufacturing

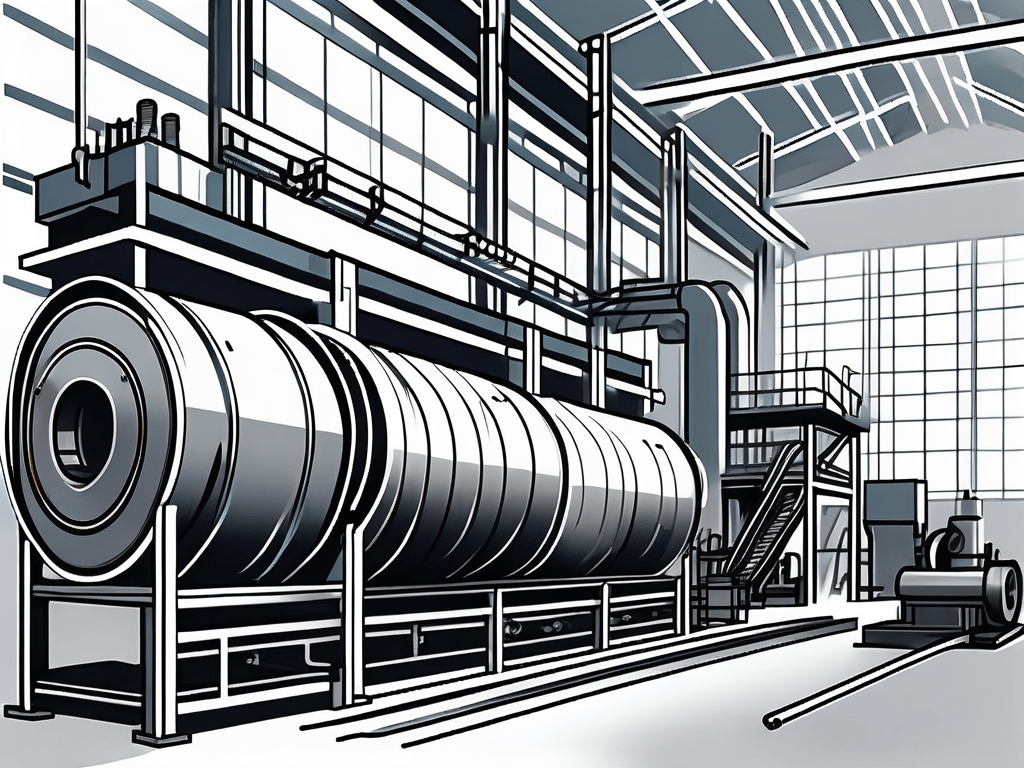

Water plays a crucial role in various stages of the steel production process. From raw material preparation to steel finishing, water is involved in cooling, cleaning, and lubrication. Water also acts as a medium for transporting fine particles during processing. These water-intensive processes highlight the significance of water in steel manufacturing.

Furthermore, water is essential for controlling the temperature of steel during different manufacturing stages. In the steelmaking process, water-cooled equipment helps regulate the heat generated by various furnaces and machinery. This precise temperature control is crucial for ensuring the quality and integrity of the final steel products. Additionally, water is used in quenching processes to rapidly cool and harden steel, enhancing its strength and durability.

The Importance of Recycling in the Steel Industry

Recognizing the finite nature of freshwater resources and the potential environmental impact of excessive water usage, the steel industry has embraced recycling as a cornerstone of its sustainability efforts. By implementing efficient water management practices, the industry has significantly reduced its reliance on freshwater sources and minimized environmental harm.

Moreover, the recycling of water in steel production not only conserves this precious resource but also reduces operational costs for manufacturers. By treating and reusing water within closed-loop systems, steel plants can lower their overall water consumption and decrease wastewater discharge. This sustainable approach not only benefits the environment but also enhances the economic viability of steel production in the long run.

The Environmental Impact of Water Usage in Steel Production

The Consequences of Water Waste in Industrial Processes

Uncontrolled water waste in industrial processes can have severe consequences for the environment. Excessive water usage can deplete local water sources, disrupt aquatic ecosystems, and degrade water quality. Additionally, the disposal of wastewater without proper treatment can exacerbate pollution levels in surrounding areas.

It is crucial for industries, especially those involved in steel production, to implement sustainable water management practices to mitigate these negative impacts. One of the key challenges is the high water intensity of steel manufacturing processes, which necessitates large volumes of water for cooling, cleaning, and other operations. Without proper conservation measures, this can strain local water resources and harm the ecosystem.

The Benefits of Water Recycling in Steel Manufacturing

Water recycling in the steel industry offers numerous environmental benefits. By recycling and reusing water, the industry reduces its demand for freshwater, thereby preserving local water sources. Furthermore, the adoption of recycling practices minimizes wastewater discharge, leading to reduced pollution and improved overall water quality.

Implementing water recycling technologies in steel production not only helps in conserving water but also contributes to energy savings. By treating and reusing water within the manufacturing processes, companies can reduce their reliance on freshwater sources and lower their energy consumption for water treatment and pumping. This dual benefit not only enhances environmental sustainability but also improves the economic efficiency of steel production.

The Economics of Water Recycling in Steel Production

Water recycling in steel production is not only beneficial for the environment but also offers significant economic advantages. By implementing water recycling technologies, steel manufacturers can reduce their reliance on purchasing freshwater and treating wastewater. This reduction in water-related costs leads to substantial savings for steel companies, allowing them to reallocate resources to enhance various aspects of their operations, such as research and development or employee training.

Cost Savings from Water Recycling

Besides the environmental advantages, water recycling in steel production also yields economic benefits. Implementing water recycling technologies reduces the need for purchasing freshwater and treating wastewater. This results in cost savings for steel manufacturers, enabling them to allocate resources to other critical areas of their operations.

Furthermore, the cost savings achieved through water recycling can contribute to improving the overall competitiveness of steel producers in the global market. Companies that adopt sustainable practices like water recycling may gain a competitive edge by appealing to environmentally conscious consumers and investors who prioritize corporate social responsibility.

The Future of Water Recycling in the Steel Industry

The steel industry is continually seeking innovative ways to enhance its water recycling capabilities. Advancements in water treatment technologies, such as filtration and purification systems, hold promise for further improving the efficiency and effectiveness of the recycling process. By embracing these advancements, the industry can continue to increase its water recycling rates and ensure a sustainable future.

Moreover, as water scarcity becomes an increasingly pressing issue globally, the steel industry’s commitment to water recycling is poised to play a crucial role in water conservation efforts. By investing in research and development to optimize water recycling processes, steel manufacturers can not only reduce their environmental footprint but also contribute to the preservation of this vital resource for future generations.

Policies and Regulations Encouraging Water Recycling

North American Policies on Industrial Water Usage

The North American steel industry operates within a regulatory framework designed to promote sustainable water usage. Government policies encourage steel manufacturers to implement water recycling practices and adopt measures that reduce their environmental impact. Compliance with these policies has been instrumental in driving the industry’s shift towards greater water recycling.

One key aspect of North American policies on industrial water usage is the establishment of water quality standards that industries must meet. These standards are set to ensure that recycled water meets certain criteria before it can be reused in industrial processes. By adhering to these standards, companies not only contribute to water conservation efforts but also safeguard the quality of water sources.

Global Trends in Water Recycling Regulations

Beyond North America, nations worldwide are recognizing the importance of water recycling in industrial sectors. They are implementing regulations that promote efficient water usage and encourage the adoption of sustainable practices. These global trends indicate a growing recognition of the need for responsible water management and the preservation of this valuable resource.

In addition to regulations focusing on water recycling, some countries are also incentivizing the development and implementation of innovative water-saving technologies. By offering grants or tax benefits to companies that invest in such technologies, governments aim to accelerate the adoption of sustainable water practices on a larger scale. This approach not only benefits the environment but also fosters technological advancements in water recycling and conservation.

Technological Advances Facilitating Water Recycling

Innovations in Water Recycling Techniques

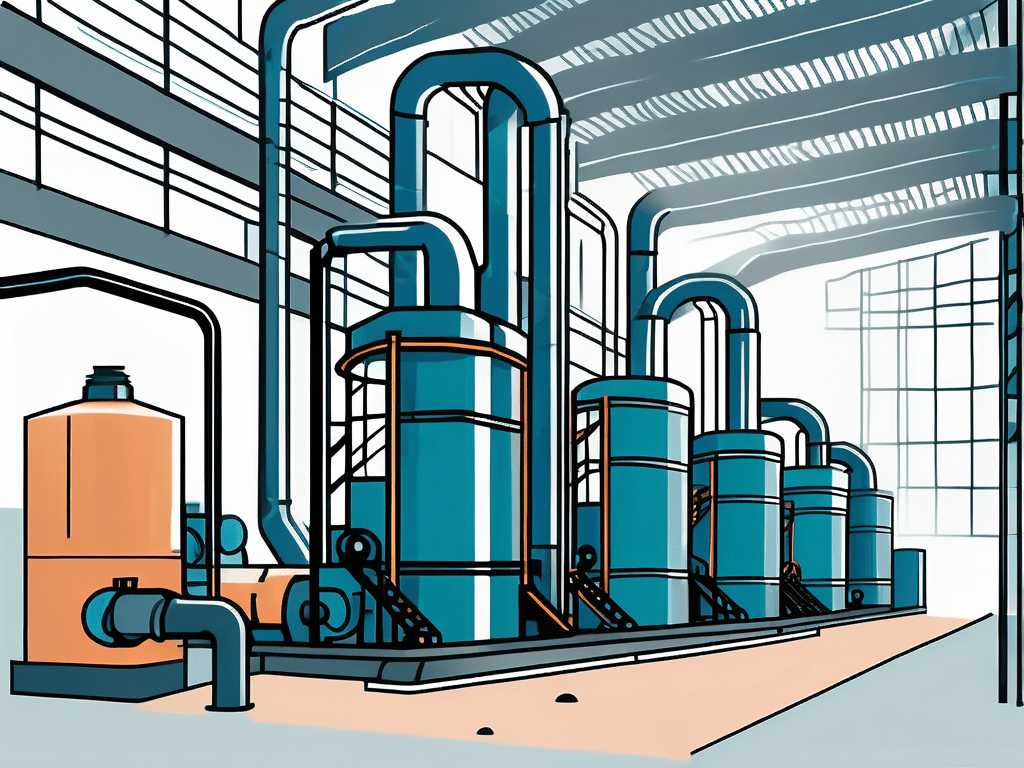

Ongoing research and development efforts have led to significant advancements in water recycling techniques for the steel industry. These innovations have revolutionized the way wastewater is treated and made it possible to efficiently remove impurities, making the water suitable for reuse. One such groundbreaking method is membrane filtration, which employs a semi-permeable membrane to separate contaminants from the water. This process ensures that even the tiniest particles, such as suspended solids and dissolved organic matter, are effectively removed.

Another remarkable innovation in water recycling is reverse osmosis. This technique utilizes a high-pressure pump to force water through a specialized membrane, leaving behind impurities and producing clean, purified water. Reverse osmosis has proven to be highly effective in removing dissolved salts, heavy metals, and other harmful substances from wastewater, making it an indispensable tool in the steel industry’s quest for sustainable water management.

The Role of Technology in Sustainable Steel Production

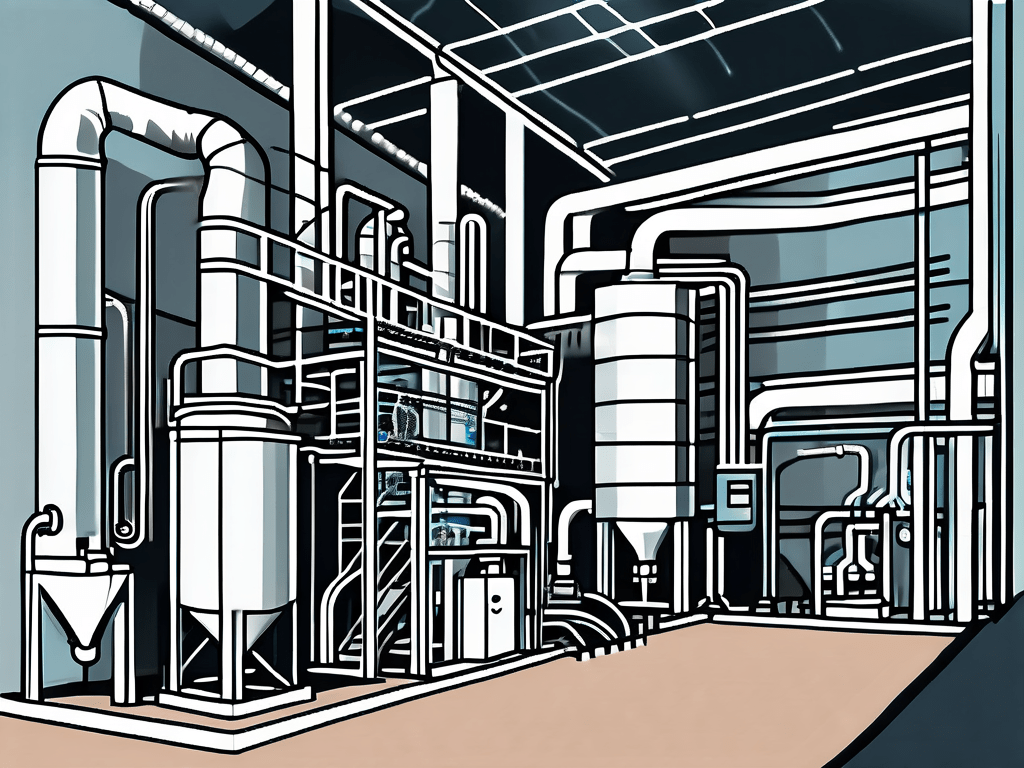

While water recycling is undoubtedly crucial for sustainable steel production, technology’s role extends far beyond that. The steel industry has made significant strides in enhancing energy efficiency, waste reduction, and emissions control through technological advancements. For instance, the implementation of advanced process control systems has allowed steel manufacturers to optimize energy consumption, minimizing the industry’s carbon footprint.

Moreover, the development of innovative waste management techniques has enabled the steel industry to reduce its environmental impact further. Advanced recycling technologies, such as electric arc furnaces and oxygen steelmaking, have made it possible to recycle scrap steel and minimize the need for raw materials extraction. This not only conserves valuable resources but also reduces the energy-intensive processes associated with traditional steel production methods.

Additionally, the steel industry has embraced cutting-edge emissions control technologies to mitigate air pollution. The use of state-of-the-art air filtration systems and advanced gas cleaning technologies ensures that harmful pollutants, such as sulfur dioxide and nitrogen oxides, are effectively captured and treated before being released into the atmosphere.

In conclusion, the steel industry’s commitment to sustainability is evident through its remarkable achievement of recycling over 95 percent of water used in North American steel production. However, the industry’s dedication to environmental stewardship goes beyond water recycling. By embracing a wide range of technological advancements, such as membrane filtration, reverse osmosis, energy-efficient processes, waste reduction techniques, and advanced emissions control systems, the steel industry is paving the way for a more sustainable and responsible future. With continuous research, supportive policies, and collective efforts, the steel industry is poised to achieve even greater resource efficiency and minimize its ecological footprint.

Leave a comment